EL Wire Soldering

Soldering EL requires some basic soldering skills and tools but is well within reach of most people. You will want the following basic tools:

• Needle nose pliers (green handle)

• Wire cutters (red handle)

• Manual wire stripper (yellow handle)

• Squeeze-style wire stripper (yellow and blue handle)

• Solder

• Copper tape (1/8" wide)

• Heat shrink tubing

• Extra wire (26 gauge works just fine)

One of the most important tools you'll want to have is a Helping Hands tool. This is basically a couple of alligator clips on a frame. You'll use extensively to hold the wire.

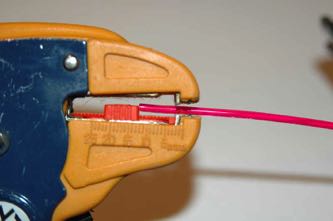

The first step is to strip the insulation off the end of the wire. The trick with stripping EL wire is removing the insulation without severing the very thin drain wire lying just underneath the insulation. For this, get a tool specifically designed to strip wires, such as the one shown. (Others are also available.) You may still lose one drain wire on occasion but you're a lot less likely to lose both.

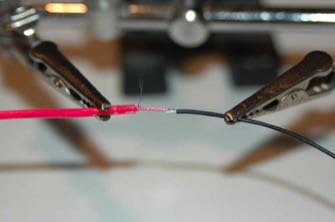

You want to remove between 1/2" and 1" worth of insulation from the end of the wire. (If you're less comfortable with your delicate soldering work, remove more insulation and give yourself room to work.) Once you do, fold the drain wires up so that they don't get in the way.

Using the wire cutters or an exacto knife, very carefully remove about 2 millimeters of the phosphorescent coating from the end of the wire. You basically want to remove the phosphor coating without putting too many nicks in the wire.

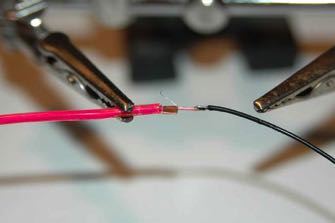

Solder a regular wire to the newly stripped EL wire end. When soldering the wires, overlap them just enough that you can get a good solder connection but not so much that the electrical wire is overlapping the remaining phosphor coating.

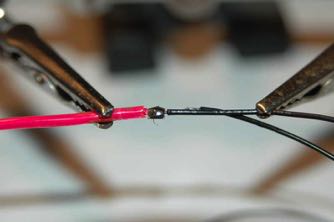

Fold the drain wire down against the phosphor. Then take a small (1/2" or less long) piece of copper tape and wrap it around the EL wire core near the insulation. Try to keep the copper tape as tight to the EL core wire as possible. Once the copper tape is in place, fold the drain wire back over the copper wire as shown.

Put your second electrical wire on top of the copper tape and fold the drain wires around it. Solder the whole thing together being careful to maintain a gap between the copper tape and the wire soldered to the EL wire core.

Once you have both wires attached, you can plug the EL wire into an inverter and test it to make sure it works. If it does, put a 1" piece of heat-shrink tubing over the entire stripped end of the EL wire to provide insulation and some stress relief. You can also use a glue gun instead of heat-shrink tubing. Basically, make sure the electrical connections are insulated and held fast to the EL wire in some way; otherwise, you may find that wires can get torn or damaged easily.